Geolam® Technology

A Legacy of Innovation

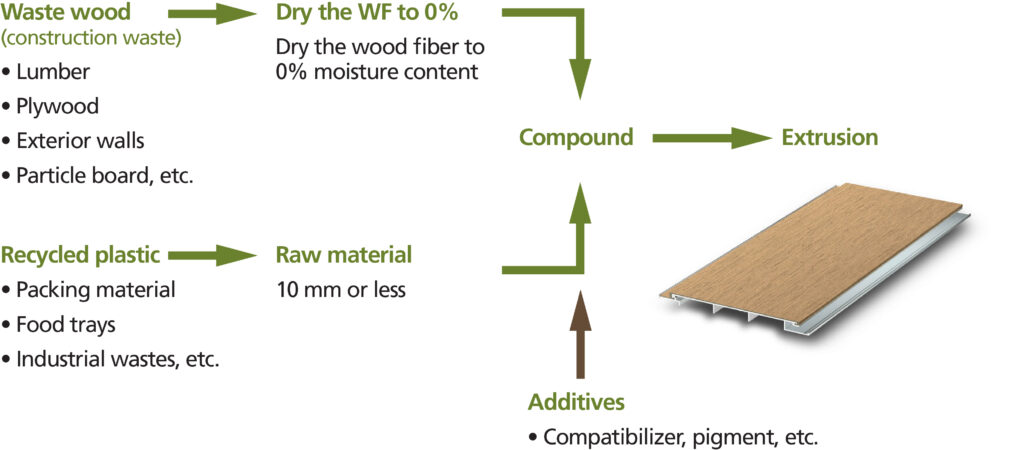

Developed in Japan in the 1990s, Geolam® is the original hybrid wood technology — a patented process that revolutionized composite materials by solving one of the industry’s biggest challenges: bonding wood and plastic.

Traditional wood-plastic composites (WPCs) struggle with moisture. Even trace amounts prevent wood fibers and plastics from adhering, resulting in weak, unstable products. Geolam® eliminates this issue by reducing wood fiber moisture content to 0%, creating a fully integrated material that’s stronger, more stable, and more natural in appearance than standard WPCs.

The Process

Wood fibers are dried through a high-intensity friction process until completely moisture-free. A thermoplastic and reinforcing agent are then added and forced into the wood’s cellular structure, forming a new, unified material — neither wood nor plastic, but a true composite.

Composition: 52% wood, 30% polypropylene, 18% stabilizers and pigments

Result: A product that looks, feels, and performs like hardwood — with the strength, stability, and longevity of engineered material.

Hybrid Technology

In 2012, Geolam introduced Wood Hybrid Systems (WHS) — the first and only profiles combining wood composite with aluminum through a patented triple-extrusion process.

Each profile features:

- Recycled Aluminum Core (6063T5): Provides lightness, strength, and extended spans between attachment points.

- Copolymer Resin Layer: Binds aluminum to the outer shell, allowing flexibility and precise bending (minimum radius: 400 mm / 16 in).

- WPC Outer Skin: Offers the beauty and texture of natural wood with exceptional dimensional stability, even under extreme temperatures.

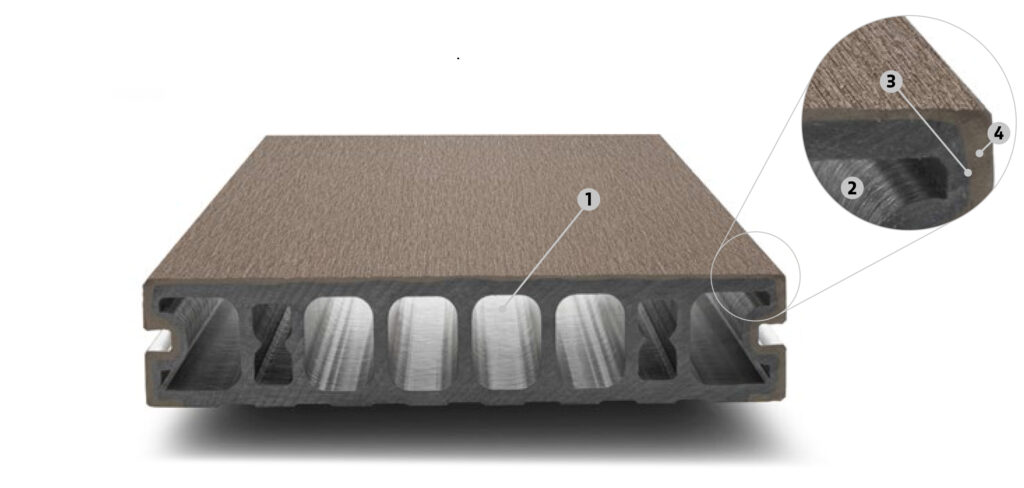

Hollow Cell Technology

Geolam pioneered the world’s first hollow cell profiles in 1992 — a breakthrough that reduced weight, increased efficiency, and minimized water absorption compared to solid decking boards.

Key Benefits

- Versatile Surface: Available in multiple colors and textures, with optional flame-retardant, anti-static, or stain-resistant properties.

- Lightweight & Strong: Honeycomb-like structure allows wider joist spacing and faster installation.

- High-Quality Extrusion: Smooth, uniform finish ensures lasting durability.

- Co-Extrusion Bonding: The core and outer layer fuse seamlessly, preventing water intrusion even at cut edges.

1. HOLLOW CELL TECHNOLOGY

Hollow cell profiles allow implementation at reduced costs due to increase of profiles inertia.

2. HIGH-QUALITY EXTRUSION

Polished surfaces are synonymous with high extrusion quality.

3. CO-EXTRUSION

Combining the core and the external layer: the material is practically homogeneous, which makes it more resistant and more stable. Even on the cut planes, water cannot penetrate between the core and the external layer.

4. EXTERNAL LAYER (WPC)

The surface of the wood composite is available in several colors, but also with different surface structures. This allows the product to be adapted to various needs. The external layer can be designed so as to have flame retardant, anti-static or stain-resistant properties.